Southeast Crane & Hoist Installs Four R&M Overhead Cranes at Alabama Foundry

The expansion is part of Tyler Union’s effort to increase capacity for low-volume and large castings.

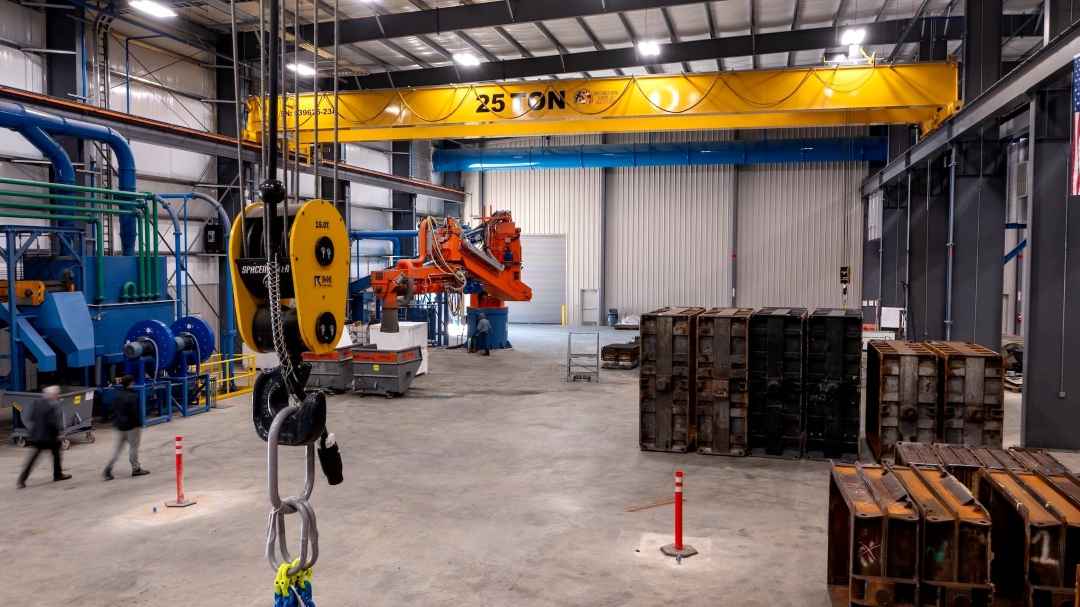

Southeast Crane & Hoist, LLC has completed the installation of four overhead cranes at Tyler Union Foundry’s new no-bake casting facility in Anniston, Alabama. The expansion is part of Tyler Union’s effort to increase capacity for low-volume and large castings.

Tyler Union, a division of McWane Inc., operates two facilities in Anniston. The main plant houses the foundry, while a secondary location handles milling and coating. Southeast Crane & Hoist is the only overhead lifting provider to have installed equipment at the foundry.

The cranes, two 25-ton models, one 15-ton, and one 5-ton, were all manufactured by R&M Materials Handling, Inc. and span 76.5 feet each, with lift heights between 28 and 29 feet. The 5-ton crane is designated for loading the electric melt furnace.

“We have a good relationship with the end user,” said Justin Glass, territory sales manager at Southeast Crane & Hoist. “The application is centered on the supply of cranes of varying capacities, each for a different type of side floor molding process.”

According to Dustin Baird, senior project and facilities engineer at Tyler Union Foundry, the expansion comes in response to increased demand. “Tyler Union has seen growth in the process and decided to get ahead of the curve,” he said.

Installation in the new building required careful planning. “We had to figure out how much room we had in the foundry to meet the customer’s requirements,” said Glass. The project also included integrating radio remote controls for improved operator safety, due to the height of the cranes and challenges with pendant use.

To reduce floor traffic and forklift dependency, a central column layout was used, and trolley cars were installed to enable movement between crane bays. “We knew the sizes of the mold and cores in the area and sized the cranes accordingly,” said Baird. “The spans and trolley coverage were calculated in line with the size of the building.”

The project was completed between June and September 2024, staying on schedule and within budget. “We have only used the cranes for setting equipment, but they have performed great so far. They run very quiet and smooth,” Baird added.

Glass noted that the installation concluded with safety training and confirmed that Southeast Crane & Hoist will continue to support Tyler Union with ongoing service and future material handling needs.

Radio control systems have already demonstrated their value as a key safety enhancement in the facility’s new operations.