CP&A Presents on Wind Load Challenges for Cranes

The paper was presented to a delegation of professionals from port authorities, terminal operators, consulting firms, dredging contractors and maritime construction companies.

Casper, Phillips & Associates Inc. (CP&A) delivered a technical presentation on wind load calculations for container cranes at the Port & Terminal Technology Conference, held April 29–30, 2025, at the InterContinental at Doral in Miami, Florida.

Mechanical engineer Richard Phillips presented CP&A’s paper titled Don’t Get Carried Away by Wind Loads to a delegation of professionals from port authorities, terminal operators, consulting firms, dredging contractors and maritime construction companies. The event, organized by MCI Media Ltd., focused on operational, maintenance and engineering challenges in the cargo handling and terminal equipment sectors.

CP&A provides a broad range of engineering services including specification, design, manufacturing review, modification and accident investigation. Phillips’ presentation centered on the length of time used to calculate wind speed, highlighting the “chaotic behavior” of wind and its consideration in crane design. He also compared regional design codes, pointing out the inconsistencies even within the same geographic areas.

“Pretty much all significant structures consider wind loads,” Phillips said. “The issue is that many structures, including quayside container cranes, may be designed to different standards, and there is often inconsistency between the definitions of wind speed. Many designers believe wind load is the most confusing and unpredictable variable they have to consider.”

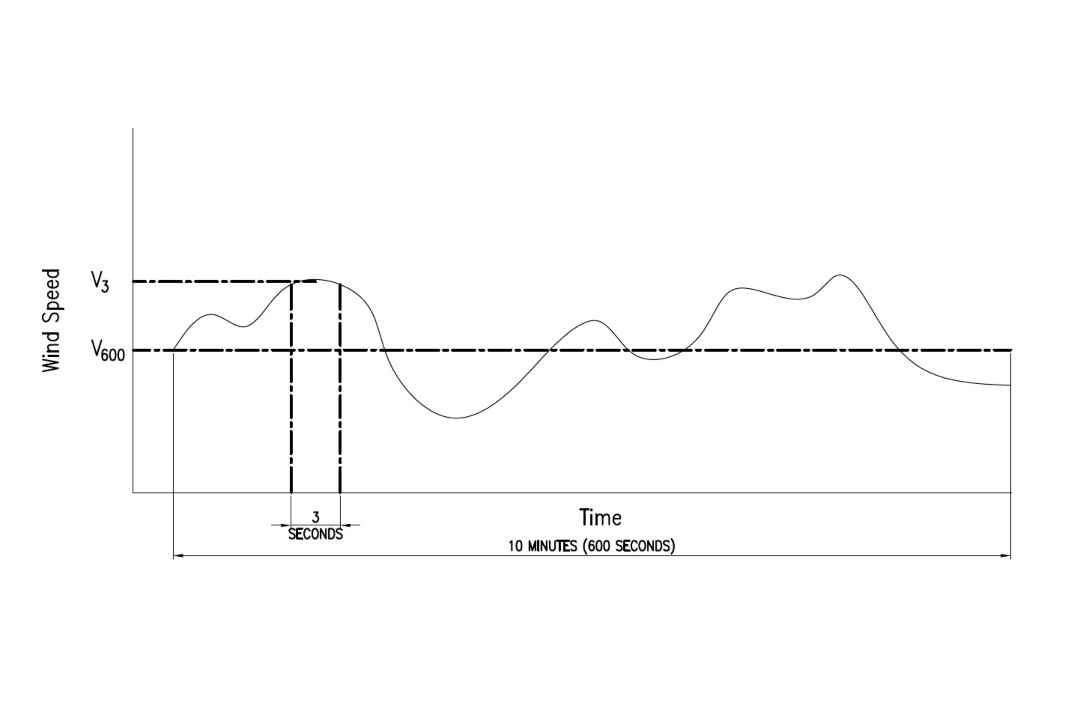

Phillips explained how wind turbulence and averaging time significantly influence recorded wind speeds. Using examples based on 10-minute and 3-second data sets, he demonstrated how different averaging periods can yield vastly different results, even when derived from the same data.

The presentation also addressed storm return periods, the interval at which a storm of a given magnitude is expected to recur. At the Miami conference venue, for example, a 50-year storm equates to winds of 127 mph, while a 700-year storm reaches 166 mph. Phillips noted that wharves often have longer design lives than cranes, making it likely they will face more extreme weather over time. As such, wharves are typically designed for longer return periods.

Phillips emphasized that international harmonization of wind load codes remains unlikely due to regional practices, local climate data and legal frameworks. Instead, he advocated for improved cross-disciplinary and cross-regional communication among crane manufacturers, port engineers and infrastructure designers.

“What we’re more likely to see, and what I think is a more realistic goal, is increased awareness and better communication,” Phillips said. “As design codes evolve, they become more and more complex; and different design codes may go about accomplishing the same goal differently. It means communication is key.”

He concluded that as the industry transitions to a new generation of engineers, a continued focus on transparency around design assumptions will be critical for advancing safe, effective infrastructure.